A new and unique plastic artform that combines 3D geometry, engineering, and artisan crafting.

Boxes

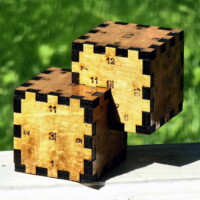

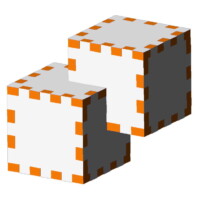

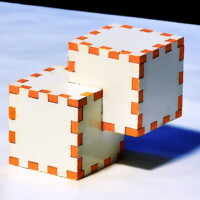

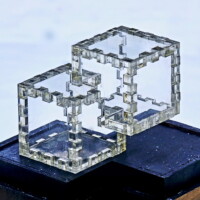

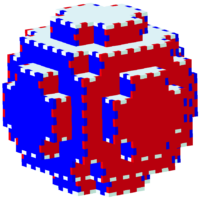

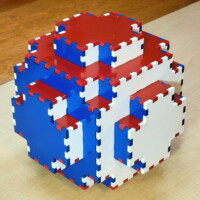

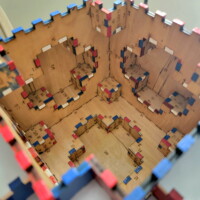

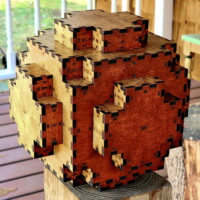

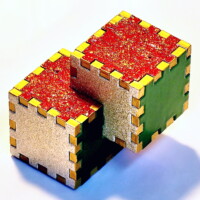

Relativity Box – A 12-piece design consisting of 2 overlapping cubes. I also used an alternate, 20-piece, 2-part design with an optional 8-piece lip.

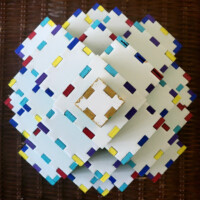

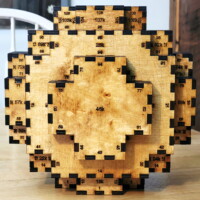

Sphere Box – A 108-piece design that approximates the shape of a sphere.

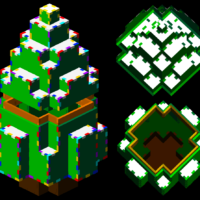

Christmas Tree Box – A 120-piece, 3-part Christmas Tree design.

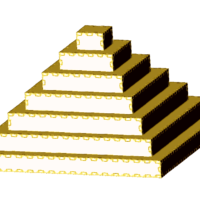

Pyrabox – A 36-piece pyramid shaped design.

Christmas 2022 Decorations Various Christmas themed boxes.

Creating a Puzzle Box / The Software

See: Puzzle Boxes: The Software for a detailed description of the software and its features.

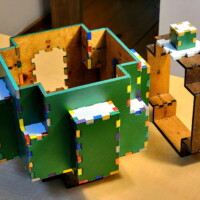

The software I wrote for this project is a design tool for making boxes using Computer Numeric Control (CNC) cutting machines. As input, it takes industry standard AutoCAD drawings, and as output it produces files that can be used to precision cut wood, plastics, and other materials for the creation of physical boxes. The sides of the boxes fit together like the pieces of a puzzle using finger joints, an assembly process common to woodworking.

Making Box Designs from Shapes

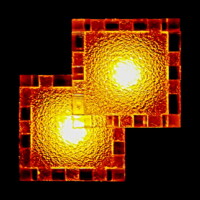

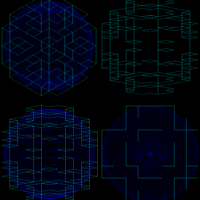

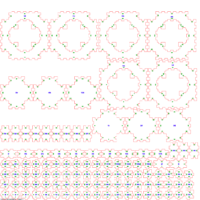

The first step in this process is to convert 3D models of arbitrary shapes (called bounding volumes) into box designs, which are assemblies of rectangular prisms. Below are examples of box designs created by the program using a sphere as a bounding volume.

The software can create box designs from more complex bounding volumes with options that control the size, shape and number of sides of the resulting designs:

In addition to box designs automatically created from a bounding volume, the software also supports box designs manually created in AutoCAD (e.g. the Relativity Box) and combination designs that were generated by the software and then manually edited (e.g. the Christmas Tree Box).

Finger Joints

The software can then read the AutoCAD model and extrude the 2D faces into into 3D pieces of one or more material thicknesses. The next step of the process is to create finger joints so that the sides of the box will fit together. Depending on whether they are on an inside or outside edge, these fingers can either add or remove material to individual pieces.

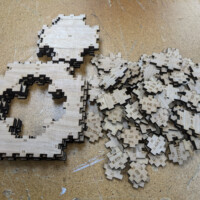

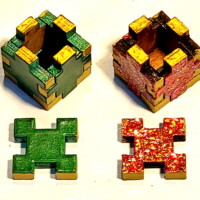

Making Boxes

Once finger joints are drawn, the program can then output instructions for a CNC machine to cut out the pieces from a sheet of material. Because these boxes can be complex, consisting of a hundred or more individual pieces, this software outputs numbers and labels for each piece, including piece numbers for each adjacent side that serve as assembly instructions.

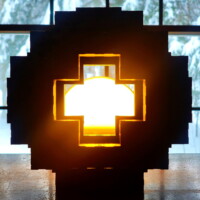

The pieces can then be decorated and assembled into a physical box.

Gallery